Dust Filter Bag Guide: Order Custom Dust Filters

Dust Filter Bag Guide: Order Custom Dust Filters

When you are ready to invest in a custom dust filter bag, you want to make sure that you are getting one that is specific to your needs. There are different types of dust filter bags and depending on your needs, you may need a specific type. So, in this guide we’ll establish what the purpose of a dust filter bag is, how it can be used, and what materials they can be made from.

Contact Us

336-372-2812

What is a Dust Filter Bag?

First off, let’s establish what a dust filter bag even is. A dust filter bag is a dust control device that is utilized to remove the dust particles contained in the exhaust gasses released through industrial processes. The dust filter bag separates dust from the exhaust gas by collecting them with the filter media. The dust is accumulated on the surface of the filter media. And the filter media is cleaned by reverse airflow called backwashing. There is a range of filter media that may be used. The materials from which the filter is made varies from polyester, heat-resistant nylon to glass fiber. The selection of the filter is dependent on conditions such as application, temperature, characteristics of gas or dust, etc.

Who Needs Dust Filter Bags?

As mentioned previously, dust filter bags are used during industrial processes. In fact, a variety of industries need and utilize dust filter bags. These industries include:

Manufacturing Industry:

This industry generates a lot of dust, so it is best to use dust collectors in factories. But it also depends on the type of goods and the number of goods being produced in the factory. In some cases, production does not generate much dust and debris, thus only one dust filter bag is needed. However, most manufacturing industries have multiple filters placed throughout the factory.

Transportation Industry:

Public transportation creates a lot of dust, dirt, and debris waste on the daily. Poor ventilation, bad air quality, and dirty engine components are all a threat to the health of employees in this industry. So, it’s vital that dust collector filter bags are used to safeguard the health of employees.

Pharmaceutical Industry:

Pharmaceuticals are the last thing we would want to be contaminated. Such contamination would be awful for a company’s reputation, their clients’ health, and ultimately would cost them a lot financially. Dust and contaminate filtration in the pharmaceutical industry acts as a safety net and prevents drug contamination.

Food Processing Industry:

This industry employs many filtration methods to keep the food quality up to standards and maintain the sanitation and hygiene of food. Using dust collection filter bags in the food processing industry is essential as it helps prevent food from getting contaminated by allergens. Some food processing plants also use custom filter bags made of fan covers and fabric ducts.

Woodworking Industry:

The woodworking industry has special dust collection needs, as the type of dust generated could be highly specific. It is important to use dust filter bags so that woodworkers can breathe easily. Using the correct dust collector filter bag makes a huge improvement in the air quality. At the end of the day, a dust filter bag can really safeguard the health of woodworkers.

Dust Filter Bag Options

There is an extensive selection of materials for dust filter bags that you may choose from. These filters are made from a range of materials which allows them to have differing capabilities. Your choice really comes down to what your needs are. Below we’ll share with you some dust filter bag options that may pique your interest.

Cotton (Woven)

Cotton dust filter bags can operate up to a maximum of 180°F. Used mostly on shaker type collectors, general applications include cleaning rooms, atmospheric air cleaning, woodworking applications, cement & rock products, and other general applications handling ambient air. Cotton filters offer good chemical resistance in dry, ambient conditions but is not recommended where mineral acids and oxidizing agents are present. While cotton filters are pretty flammable, they are available with a flame-retardant finish.

Polyester

Polyester dust filter bags can operate to a maximum of 275°F. These are the most common filter bags. Polyester bags offer great resistance to chemicals, abrasion, and dry heat degradation. They have excellent dimensional stability and are good for dry heat applications. However, they are not the best choice for moist heat and are subject to hydrolytic degradation. Polyester offers good resistance to most mineral and organic acids except high concentration of nitric, sulfuric, and carbolic acids.

Polypropylene

Polypropylene dust filter bags can operate to a maximum temperature of 170°F. Polypropylene is used for general applications where chemical and moisture attacks other fibers. Moisture absorption is virtually non-existent. This material offers high strength and excellent resistance to most acids and alkalis. Polypropylene also has fair resistance to most organic solvents.

Nylon

The normal maximum continuous operating temperature for nylon dust filter bags is 250°F. Nylon is typically used for highly abrasive dust applications. It has good resistance to alkalis under most conditions, but most mineral oxides cause degradation and partial decomposition. This material does hold up to common organic solvents very well.

Acrylic

Acrylic dust filter bags can operate up to a maximum of 275°F. Its general applications include dryers, electric furnaces, aluminum reduction, and primary or secondary smelting. This material can resist most mineral and organic acids. Acrylic, also, has fair resistance to most oxidizing agents but excellent resistance to most organic solvents. However, it is not available in all fabric forms and is more costly than polyester or polypropylene.

Fiberglass

Fiberglass has a much higher temperature resistance compared to other materials. It can operate normally up to a temperature of 500°F. Its general applications include cement kilns, high temperature dryers, carbon black reactors, power plants, and electric furnaces. Fiberglass has excellent resistance to most acids, with the exception of hydrofluoric acid. This material has poor flex abrasion qualities and requires a 20 vertical wire minimum support cage when used in tubular bag form.

How do I Order Custom Dust Fitler Bags

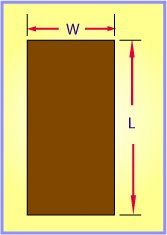

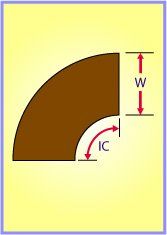

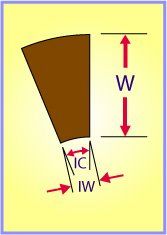

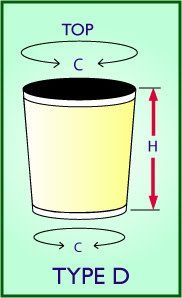

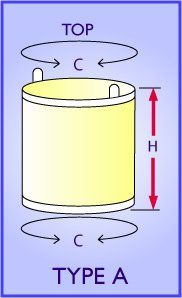

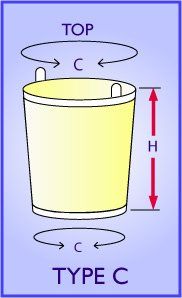

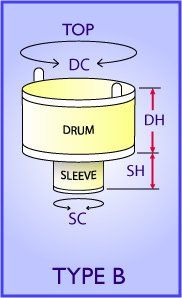

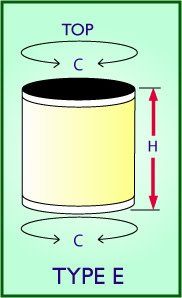

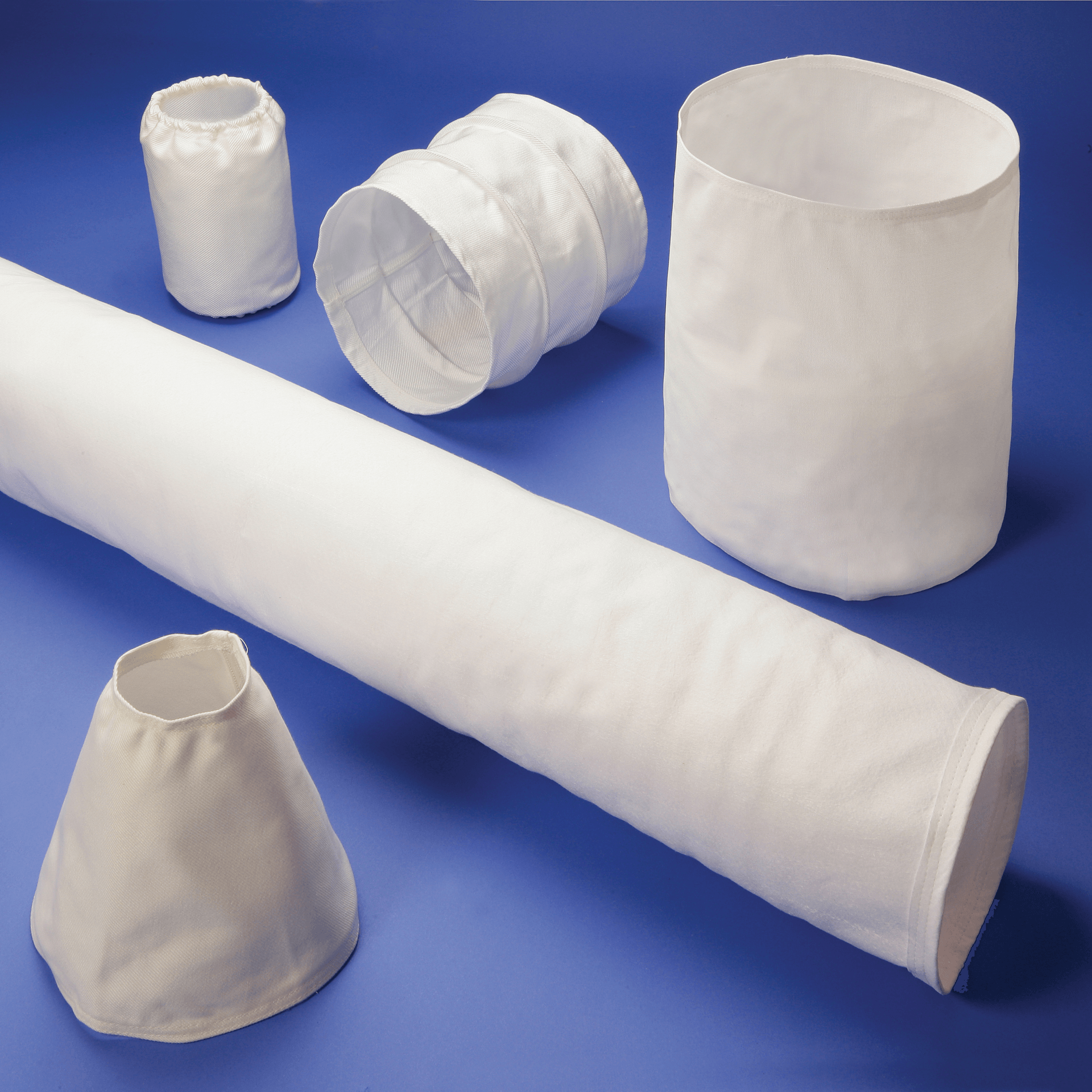

Here at Parker Sales & Service, we can offer you your own custom dust filter bag. In our 60 years of fine service, we have built a notable reputation for our custom engineering. We have a wide range of filtration products and connecting sleeves from woven or felted material. Thanks to our extensive selection of materials, we can offer you a variety of solutions to your filtration needs. Our long-lasting dust filter bags can be made to any dimension from woven and nonwoven (felted) media. Chemically inert natural and synthetic fibers and high-temperature materials are available. If you look through our website, you’ll find the list of materials we offer and from there, you can choose which will best suit your needs.

Talk to the Dust Filter Experts at PSAS, Inc.

Customer Focused. Solution Driven.

Talk to Our Filter Experts at PSAS, Inc.

Here at Parker Sales & Service, we can offer you your own custom dust filter bag. In our 60 years of fine service, we have built a notable reputation for our custom engineering.